Why Business Leaders Must Prioritize Supply Chain Digital Transformation

The supply chain landscape is evolving at an unprecedented pace. To remain competitive and resilient, businesses must adapt to key drivers that are reshaping supply chain operations. Understanding these forces is critical to implementing an effective digital transformation strategy.

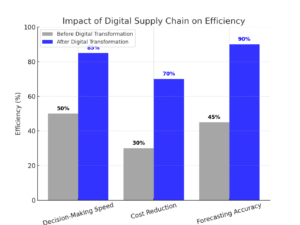

The data reinforces a clear trend—supply chain success is increasingly dependent on digital transformation. Organizations that embrace automation, AI-driven forecasting, and real-time analytics gain the agility to navigate disruptions and optimize operations.

But what exactly is driving this shift?

What’s Driving Digital Supply Chain Transformation?

The modern supply chain is no longer just about moving goods from point A to B—it’s about resilience, efficiency, and adaptability in an unpredictable world. Businesses must embrace digital transformation to stay ahead of disruptions, meet evolving customer demands, and drive sustainable growth. Here are the key forces reshaping supply chain strategies today:

1. Evolving Customer Expectations: The Demand for Speed, Customization, and Transparency

Today’s consumers expect on-demand, hyper-personalized experiences with rapid and reliable fulfilment. Instant gratification has become the norm, fuelled by eCommerce giants, next-day deliveries, and AI-driven recommendations that shape purchasing behaviours.

- Customer-driven supply chains now demand greater flexibility, real-time tracking, and seamless fulfilment options.

- Digital supply chains leverage AI-powered demand forecasting and last-mile logistics automation to meet these expectations efficiently.

- Connected ecosystems integrate real-time inventory visibility across multiple sales channels, ensuring stock availability and reducing fulfilment delays.

2. Unpredictable Disruptions: Navigating Volatility with Digital Resilience

From geopolitical conflicts to pandemics and climate change, disruptions are the new reality for global supply chains. The increasing frequency of these challenges exposes vulnerabilities in traditional, rigid supply chain models.

- AI-driven risk analytics identify vulnerabilities in supplier networks and anticipate potential bottlenecks.

- Cloud-based digital twins allow businesses to simulate disruptions, assess risks, and optimize response strategies in real time.

- Agile digital supply chains deploy automated contingency planning, ensuring adaptability to changing global conditions.

3. Sustainability & Compliance: Meeting Regulatory and Ethical Standards

Sustainability is no longer optional—it’s a business imperative. Governments and consumers alike demand responsible sourcing, lower carbon footprints, and end-to-end supply chain transparency.

- Blockchain technology enables traceability by recording every transaction and movement, ensuring ethical sourcing and regulatory compliance.

- AI-powered route optimization minimizes carbon emissions by reducing unnecessary transportation miles.

- Circular supply chain models promote recycling and resource efficiency, aligning businesses with ESG (Environmental, Social, and Governance) goals.

4. Operational Efficiency & Cost Reduction: The Role of AI, IoT, and Automation

Efficiency is the backbone of profitable supply chain management. The adoption of AI, IoT, and robotic automation is eliminating inefficiencies and cutting costs at every stage.

- Predictive maintenance with IoT prevents downtime by analysing equipment health in warehouses and logistics hubs.

- AI-driven process automation streamlines repetitive manual tasks, reducing errors and accelerating supply chain workflows.

- Data-driven decision-making enhances procurement, logistics, and inventory management, ensuring leaner and more cost-effective operations.

Unlock the Power of a Digital-First Supply Chain

Gain real-time visibility, optimize workflows, and future-proof your operations with AI-driven supply chain solutions.

Schedule a Consultation

5. Competitive Differentiation: Winning with Data-Driven, Adaptive Supply Chains

In a hypercompetitive landscape, companies that embrace digital supply chain transformation gain a significant edge over competitors. Businesses that fail to modernize risk losing market share to more agile competitors.

- AI-powered demand sensing helps businesses anticipate market trends and proactively adjust inventory levels.

- Smart contracts via blockchain streamline supplier agreements, reducing delays and boosting transaction efficiency.

- Digital ecosystems create seamless collaboration between suppliers, logistics providers, and customers, enhancing the overall value chain.

By leveraging digital technologies, organizations can future proof their supply chains, improve customer satisfaction, and drive revenue growth. The companies leading this transformation are those that embrace agility, real-time intelligence, and automation as core pillars of supply chain strategy.

Traditional vs. Digital Supply Chains

| Aspect | Traditional Supply Chain | Digital Supply Chain |

| Data Management | Manual, paper-based records | Real-time, cloud-based data sharing |

| Decision-Making | Slow, reactive decision-making | AI-driven, predictive decision-making |

| Automation | Minimal automation, labour-intensive | High automation, robotics-enabled workflows |

| Visibility | Limited, fragmented visibility | End-to-end transparency & real-time tracking |

| Collaboration | Siloed communication between stakeholders | Seamless collaboration via digital platforms |

| Efficiency | High operational inefficiencies | Optimized processes & cost reduction |

| Scalability | Difficult to scale operations | Easily scalable with flexible infrastructure |

| Risk Management | High risk of disruptions with slow response time | Proactive risk management using AI & analytics |

The Technologies Reshaping the Digital Supply Chain

1. AI & Machine Learning: The Foundation of Predictive and Prescriptive Supply Chains

AI-driven supply chains move from reactive to predictive and prescriptive models. Machine learning algorithms analyse historical and real-time data to forecast demand, optimize procurement, and predict potential disruptions before they occur.

For decision-makers, this means moving beyond traditional forecasting and implementing self-correcting supply chain models that dynamically adjust based on market signals.

2. IoT-Enabled Visibility: Real-Time Data for Smarter Decisions

The Internet of Things (IoT) revolutionizes visibility across the supply chain. GPS trackers, RFID tags, and connected sensors provide real-time monitoring of shipments, warehouse conditions, and equipment performance.

Companies that adopt IoT-driven visibility see improved operational efficiency, enhanced risk mitigation, and lower costs due to proactive interventions.

3. Blockchain for Supply Chain Integrity and Transparency

Blockchain enhances trust and transparency by creating tamper-proof digital records for every transaction in the supply chain. This is particularly crucial in pharmaceuticals, food safety, and high-value commodities, where traceability is non-negotiable.

Leaders investing in blockchain-powered supply chains gain faster dispute resolution, enhanced supplier accountability, and stronger regulatory compliance.

4. Cloud & Big Data: Enabling an Intelligent, Scalable Supply Chain

Cloud-based supply chain solutions break down data silos and ensure real-time collaboration between suppliers, manufacturers, and logistics providers. Big data analytics extracts actionable insights from massive datasets, helping businesses make faster, data-driven decisions.

Organizations leveraging cloud supply chain platforms report:

- 35% faster decision-making cycles

- 20% improvement in supply chain efficiency

- Higher accuracy in demand forecasting

5. Robotics & Automation: From Warehouses to Last-Mile Logistics

Autonomous robotics and AI-powered automation are streamlining warehouse operations and fulfilment processes. Robotic picking systems, autonomous guided vehicles (AGVs), and AI-driven demand-supply balancing are redefining efficiency.

Retail and eCommerce players are already adopting autonomous delivery solutions, with self-driving trucks and drone deliveries emerging as viable logistics options.

The Future of Supply Chain Digital Transformation

Business leaders must take a proactive rather than reactive approach to supply chain modernization. The future belongs to organizations that anticipate trends, invest in agility, and deploy emerging technologies before disruption forces their hand.

1. Predictive Analytics & AI-Driven Demand Forecasting

Modern supply chains will operate with real-time adaptability, leveraging AI to predict demand fluctuations, optimize routing, and mitigate risks before they materialize.

2. Sustainability as a Competitive Advantage

Green supply chains will be a differentiator and a requirement. Enterprises will integrate:

AI-driven route optimization to reduce emissions

Smart packaging solutions to minimize waste

Circular supply chain models for responsible resource utilization

3. Autonomous Logistics & Smart Warehousing

The rapid evolution of robotics, AI-driven logistics hubs, and self-learning supply chain models will shape a world where supply chains operate autonomously with minimal human intervention.

4. Cybersecurity in a Hyperconnected Supply Chain

As supply chains become increasingly data-driven and interconnected, cybersecurity risks multiply. The next wave of digital transformation will see a stronger focus on end-to-end encryption, AI-powered threat detection, and blockchain-based security measures.

From Insight to Action: Building a Digital-First Supply Chain

A forward-thinking approach to supply chain transformation requires more than just adopting new technologies—it necessitates a paradigm shift in strategy, collaboration, and execution.

To stay ahead, organizations must:

- Invest in AI-powered insights to make informed, proactive decisions.

- Foster a data-driven culture where teams leverage predictive analytics for smarter forecasting.

- Enhance collaboration with suppliers and logistics partners through digital platforms.

- Strengthen cybersecurity frameworks to protect critical supply chain data from breaches.

Companies that embrace agility, automation, and intelligence in their supply chain strategies will lead the next era of operational excellence and market leadership.

Conclusion: A Future-Ready Supply Chain Starts Today

The digital supply chain is no longer a distant vision—it is an immediate necessity for businesses looking to drive efficiency, reduce risk, and build resilience in an unpredictable global landscape.

As a partner in digital innovation, Neuronimbus empowers organizations with cutting-edge solutions designed to enhance visibility, optimize workflows, and streamline operations through advanced digital technologies.

Organizations that seize the opportunity to digitize now will not only future proof their supply chains but will also establish a foundation for sustained growth, adaptability, and long-term success.