Redefining Inventory: What Is an Intelligent Inventory Management Solution?

Today’s smart inventory management goes well beyond simple tracking or record-keeping. It represents a fundamental leap in visibility, automation, and real-time control.

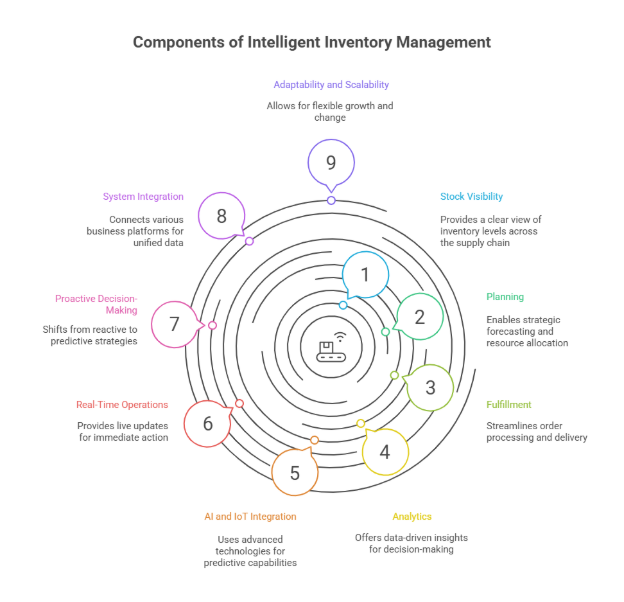

- Definition of a Smart Inventory System: At its essence, a smart inventory system is a software- and data-driven ecosystem that unifies stock visibility, planning, fulfillment, and analytics across every node of the supply network, from warehouse shelf to omnichannel customer.

- Distinguishing from Legacy Systems: Unlike traditional systems, intelligent platforms harness artificial intelligence, machine learning, and Internet of Things (IoT) technologies to anticipate, rather than merely react to, inventory signals and market conditions.

- Focus on Real-Time Operations: Central to these systems is an always-live dashboard that surfaces inventory movements as they happen, empowering teams to take timely action based on accurate, granular information.

- Proactive, Not Reactive: With predictive and prescriptive analytics, businesses shift from crisis-driven decisions (such as emergency reordering or markdowns) to optimized, forward-looking planning and replenishment.

- Integration as a Mandate: Intelligent systems connect seamlessly with ERP, CRM, warehouse management, and eCommerce platforms, breaking down information silos and fostering a unified business view.

- Adaptability and Scalability: Built on modular and cloud-ready architectures, these platforms flex to accommodate expansion, diversification, or new business models as organizations grow.

By leveraging these capabilities, businesses are empowered to shift from “survival mode” to “innovation mode”—driving transformation in supply chain performance and market responsiveness.

Mission-Critical Capabilities of Modern Inventory Platforms

A modern, enterprise-class inventory platform brings together a diverse array of features. Each capability addresses a crucial aspect of supply chain success, setting a new benchmark for operational excellence.

- Continuous, Real-Time Visibility: Systems that offer instant snapshots of stock across every warehouse, store, and distribution partner reduce uncertainty and support immediate, informed action on all inventory decisions.

- Intelligent Demand Planning and Forecasting: AI-driven models scan historical data, market trends, promotions, and external variables to project inventory needs, adjust allocations, and mitigate risks of both understock and excess.

- Automated Replenishment and Workflow Orchestration: Rule-based triggers initiate restocking and notify stakeholders, ensuring product availability and minimal manual touchpoints—significantly reducing delays and costly errors.

- Seamless System Integration: Direct interoperability with procurement, finance, sales, and CRM ensures alignment, accelerates business processes, and improves data reliability for strategic planning and auditing.

- Granular Analytics, KPIs & Reporting: Actionable insights—turnover rates, holding costs, category profitability, and supply chain bottlenecks—are delivered through robust analytics engines, supporting data-driven continuous improvement.

- Multi-Channel Synchronization: These systems ensure inventory consistency across eCommerce storefronts, wholesale, brick-and-mortar, and third-party marketplaces, meeting modern customer expectations for product availability regardless of channel.

- Dynamic Safety Stock and Buffer Optimization: Algorithms continuously recalculate safety stock targets based on lead-time trends, demand volatility, and supplier performance, keeping inventory lean yet resilient.

- Returns & Reverse Logistics Automation: Smart workflows streamline customer returns and restocking, closing the loop on product lifecycle management, enhancing transparency, and supporting sustainable operations.

- Audit-Ready Compliance and Traceability: Automated record-keeping and digital trails simplify audits, reduce compliance risks, and deliver full transparency throughout the value chain.

Together, these features form the operational foundation for a truly intelligent, customer-centric, and change-ready supply chain.

Foundations for a Future-Resilient Supply Network

Resilience—the capacity to absorb shocks, adapt, and emerge stronger—is rapidly becoming the highest ideal in supply chain management. Smart inventory solutions are at the heart of building this future.

- Breaking Down Data Siloes: Consolidated platforms dissolve legacy barriers, enabling oversight and collaboration across all teams and partners, making “one version of the truth” accessible to every stakeholder.

- Accelerating Response to Risk: Predictive analytics detect disruptions or shifting demand, supporting real-time contingency planning and swift redistribution of resources in response to market or supplier challenges.

- Driving Lean and Agile Operations: Automation cuts redundancy and waste, ensures tighter stock cycles, and helps organizations pivot rapidly to exploit new opportunities or reduce exposure as conditions evolve.

- Strengthening Customer Experience: Inventory precision and speed ensure that orders are filled accurately and promptly—a non-negotiable standard in an era of direct-to-consumer fulfillment and omni-channel retailing.

- Supporting Scalability and Growth: Modular, scalable platforms flex to accommodate entry into new regions, lines of business, or sales channels—without sacrificing performance, control, or strategic alignment.

- Ensuring Transparency and Traceability: By tracking products, components, and suppliers throughout the journey, smart systems support compliance, accountability, and partnerships founded on trust.

- Enhancing Supply Chain Collaboration: End-to-end visibility promotes shared KPIs and integrated planning among trading partners, unlocking greater efficiency and responsiveness to market shifts.

- Enabling Sustainability Initiatives: Data-driven stock control reduces overproduction, shrinkage, and waste, facilitating sustainable supply chain practices and supporting environmental, social, and governance (ESG) goals.

In essence, future-resilient supply chains are built not only on efficiency but also on agility, transparency, and intelligent responsiveness—qualities that smart inventory platforms now deliver at scale.

Demonstrated Industry Success: Use Cases of Intelligent Inventory

The power of smart inventory management is proven across multiple sectors. Leading organizations report game-changing performance improvements by deploying these advanced solutions.

- Retail Sector: An international retailer leveraged AI-powered inventory to increase in-stock rates by 25%, while simultaneously cutting overstock and markdown events through real-time replenishment and demand prediction.

- Manufacturing: A precision electronics manufacturer utilized integrated IoT and AI inventory platforms for just-in-time production, slashing material waste and boosting throughput by automating reorder and stock allocation workflows.

- Healthcare and Pharmaceuticals: A hospital group adopted cloud-based inventory software to monitor and distribute life-saving medical supplies, reducing critical stockouts by 40% and ensuring compliance with safety regulations.

- Logistics and Warehousing: By deploying sensors and predictive analytics, a 3PL provider optimized storage utilization, reduced carrying costs, and enabled accurate forecasting for contract customers during peak periods.

- E-commerce: A digital-first retailer consolidated inventory data across multiple marketplaces, boosting order fill rates and eliminating lost sales caused by “phantom stock” or manual reconciliation errors.

- Food and Beverage Sector: A global F&B company automated lot tracking and temperature monitoring, ensuring food safety, minimizing spoilage, and streamlining regulatory audits with digital traceability.

- Automotive and Spare Parts: Parts distributors used AI-enabled forecasting and multi-location tracking to slash fulfillment lead times and automate stock rebalancing between warehouse locations, driving improved dealer satisfaction.

These cases reflect the transformative impact of modern inventory management—from accuracy and efficiency to resilience, transparency, and customer experience.

Ready to Reimagine Your Inventory?

Empower your supply chain with the intelligence and agility of a next-generation inventory management platform.

Request a Strategy Consultation

Transformation in Action: Client Impact Stories

Behind every statistic is a business that has accelerated its growth, improved operational certainty, and delivered greater value through intelligent inventory systems.

- Digital Retail Leader: An Asia-Pacific eCommerce firm partnered with a technology consulting team to overhaul its legacy inventory process. The resulting cloud-based system provided real-time stock across 200+ locations, supporting flash sales, same-day shipping, and a 30% reduction in stockholding costs.

- Regional Healthcare Provider: A hospital network automated its inventory surveillance using IoT sensors and smart analytics. The solution flagged imminent shortages, prevented critical supply interruptions, and freed up staff hours previously spent on manual checks.

- Specialized Manufacturer: A mid-size auto components supplier leveraged integrated demand planning, connecting sales, production, and procurement with advanced analytics. Benefits included a 20% reduction in inventory carrying costs and much tighter alignment between production and market demand.

- Global 3PL Logistics Firm: A leading logistics brand implemented AI-based SKU forecasting and automated replenishment, optimizing warehouse space and slashing order-to-delivery windows during seasonal surges.

- Grocery Chain Transformation: By integrating data across store, online, and warehouse channels, a grocery company eliminated inventory “blind spots,” reduced food waste, and became more responsive to shifting consumer buying behavior—gaining an edge over traditional competitors.

- Pharma Supply Security: With automated digital compliance tracking, a pharmaceutical distributor minimized expired stock losses, facilitated swift regulatory audits, and ensured uninterrupted availability of essential drugs.

These stories demonstrate that the adoption of smart inventory platforms is not just a technological upgrade; it is a catalyst for reshaping business strategy and outcomes across industries.

How Can Neuronimbus Enable Your Smart Inventory Transformation?

As a digital consulting and solutions leader, Neuronimbus brings future-ready innovation, proven industry frameworks, and deep domain expertise to businesses aiming to modernize inventory and supply chain operations. With a client-centric approach honed across Australia and global markets, Neuronimbus specializes in designing and building robust, scalable, and intelligent inventory management systems tailored to your business vision.

From initial assessment, our consultants engage with stakeholders to understand your specific challenges, operational bottlenecks, and strategic goals. We then devise a digital roadmap—integrating advanced automation, real-time dashboards, predictive analytics, and IoT-enabled data capture. Our solutions are built on best-in-class, cloud-based architectures, ensuring that your inventory strategy remains both agile and resilient.

Neuronimbus leverages artificial intelligence for demand planning, automates stock movement and replenishment, and unifies multi-channel inventory synchronization with seamless ERP and CRM integration. Security, compliance, and data integrity are woven into every layer of the solution architecture—so your business can scale with confidence and meet stringent audit demands. Our IoT and analytics capabilities provide granular, actionable insights—turning raw data into business-critical intelligence for rapid decision-making.

What sets Neuronimbus apart is not just technology delivery, but ongoing partnership. We provide organizational change management to upskill your teams, drive adoption, and embed a culture of continuous improvement. Clients receive proactive 24/7 support and benefit from our commitment to ongoing innovation—keeping your inventory system at the forefront as business models, regulations, and technologies evolve.